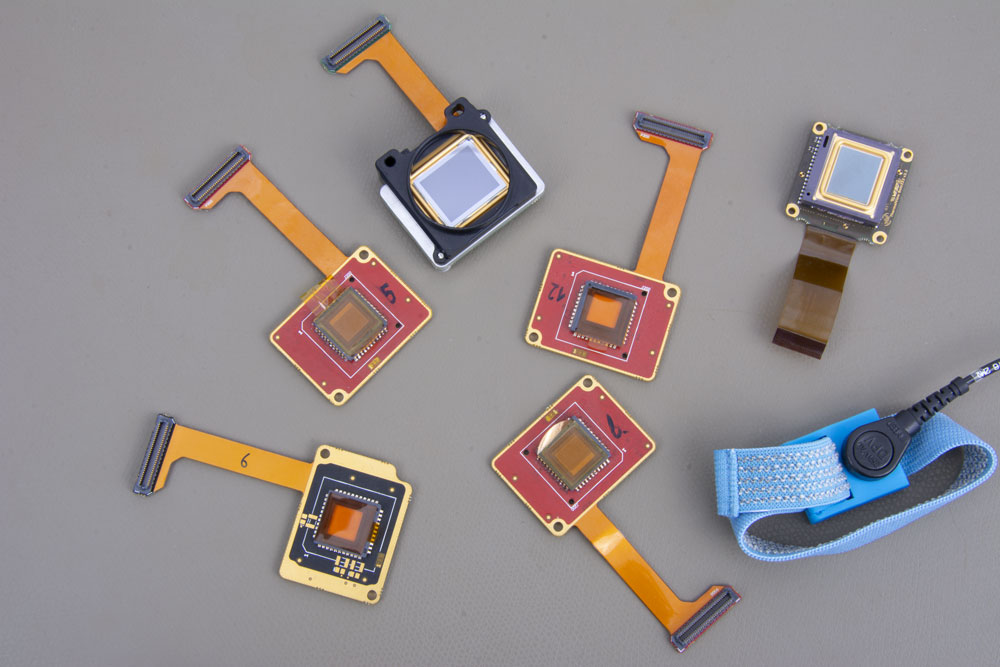

Instead of purchasing off-the-shelf thermal imaging cores, VECTED uses its optoelectronics expertise to develop and produce its own components completely in-house, before integrating them into its thermal imaging cameras. This encompasses all the electronics and image processing operations – from the sensor frontend to the display backend. We build a fully integrated system that includes an LWIR microbolometer (sensor) and a micro-OLED display and creates a deep connection between their controllers as well as image processing and the user interface. The result is a product specifically tailored to the user’s application and without any prefabricated components.

A fully integrated system instead of off-the-shelf thermal imaging cores

High-contrast images thanks to in-house image processing system

Another feature that sets our thermal imaging cameras apart is the image processing system developed internally by VECTED, which allows images to be continuously analysed in real time and image parameters to be automatically updated. This produces a natural, high-contrast image that is similar to that of a high-quality black-and-white picture. The system also ensures that details are not lost due to over- or underexposure.